Special Purpose Machines

Special Purpose Machines, commonly known as SPM machines, are mostly unavailable off the shelf. Unlike other machines, these don't fall in the category of standard manufacturing programs. These machines are specially designed and tailored as per one's specific demand. SPMS are also known as bespoke machines and specially designed machines.

Also, as the name suggests, special purpose machines are crafted to deal with special tasks such as fulfilling mass demands, producing materials with complete automation and so on. In this blog, we will help you know the usage and working of SPM machine, followed by some real example of SPMs. Towards the end, we will also tell you some advantages and disadvantages of these machines.

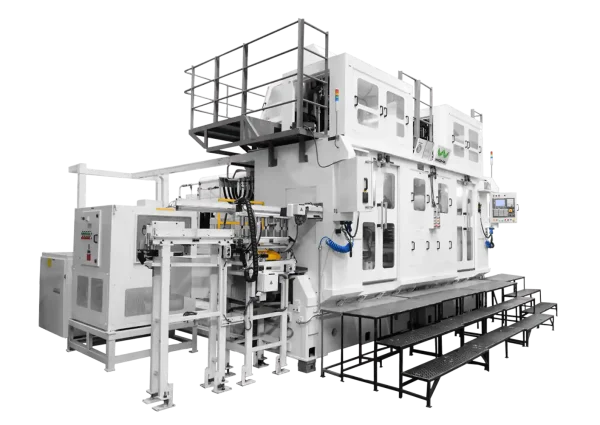

Multi-operation Rotary Indexing Machines

WINMAR rotary machines are designed for simultaneous execution of multiple operations like drilling, tapping, rough boring, fine boring, spot facing, and reaming. These special-purpose machines are usually handled by a single operator. This offers the benefit of the best possible productivity and cycle time.

Typical Components

- Cylinder head

- Crank shaft

- Compressor Crankcase

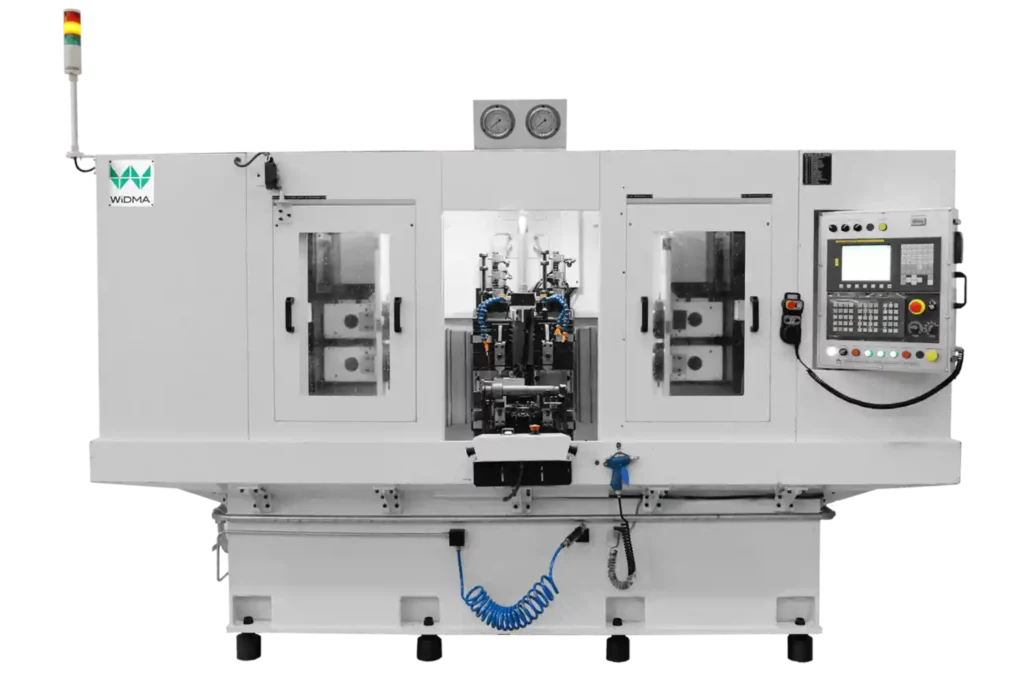

Valve Seat Machining and Valve Guide Reaming

Built for accurate machining of valve seat profiles and valve guides for engine cylinder heads, these machines span a range of diameters for generation and plunging. WINMAR is the first to develop these special purpose machines indigenously in India.

Typical Components

-

Cylinder head for four-wheelers and heavy vehicles

Fine Boring Machines

WINMAR offers fine boring machines of vertical and horizontal configurations with single or multiple spindles. The tool correction feature of these machines works up to an accuracy of 1-micron diameter. Besides, the tool retracts mark can be eliminated during tool return. Bore tolerances from IT6 to IT8 and surface finish of 0.8 to 1.6μ Ra. can be achieved, depending on the material of the component.

Typical Components

- Cylinder head

- Connecting rod

- Cylinder block

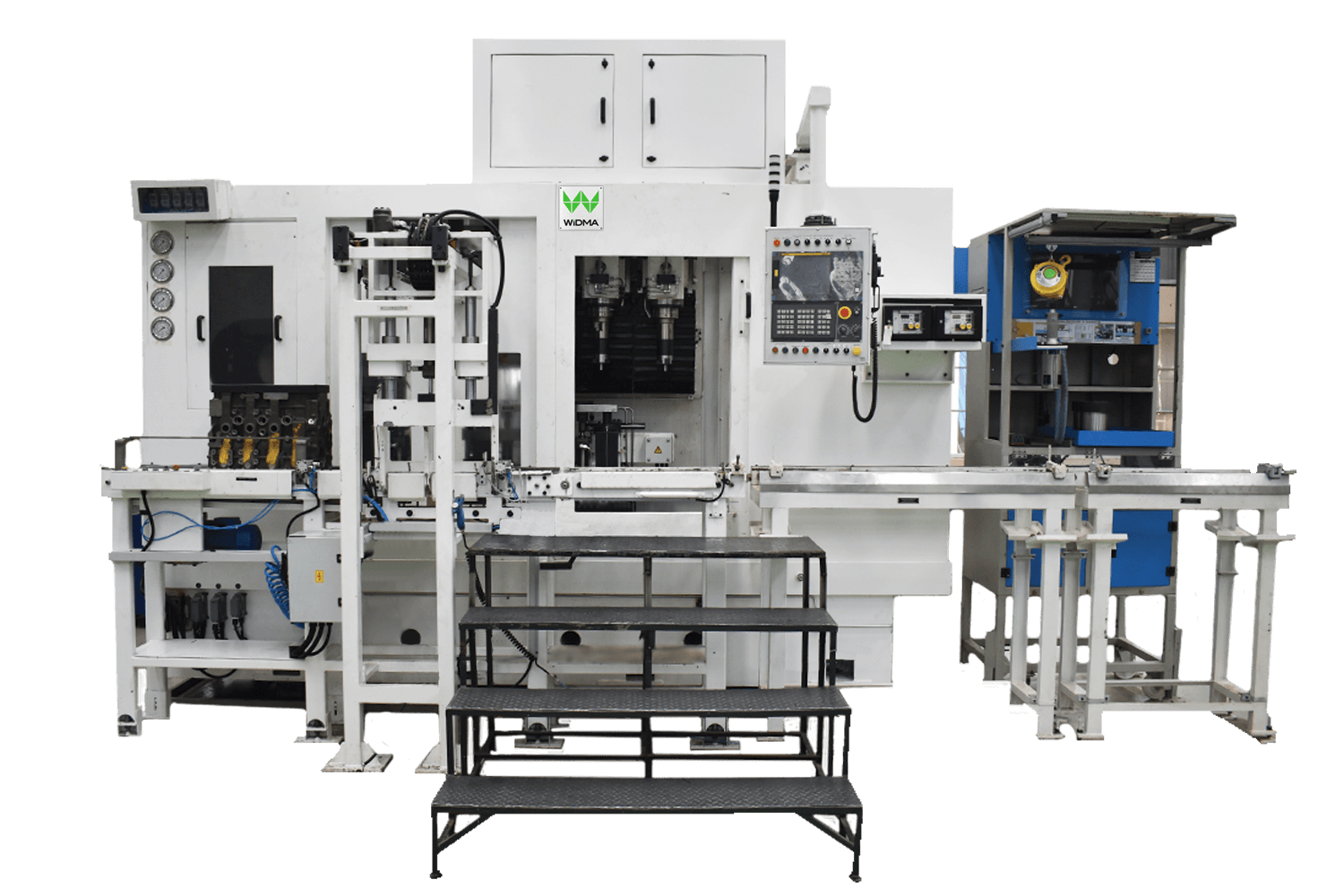

Multi-spindle Machines

WINMAR multi-spindle special purpose machines are built to perform multiple operations simultaneously and offer the best-in-class cycle time. Available in horizontal and vertical configurations, they can be provided with rotary or linear indexing. These machines can be used for operations such as drilling, tapping, rough boring, fine boring, reaming, and spot facing.

Typical Components

- Crankcase and crankcase cover

- Cylinder head

- Cylinder block

Facing and Centering Machines

WINAMR facing and centring machines are available in both vertical and horizontal configurations with slides for plunge or traverse milling. They provide accurate centre and face references for further operations like turning and grinding.

- Two spindle machine for smaller shafts

- Four spindle machine for shafts of larger diameter

Typical Components

- Cam shaft

- Turbine shafts

- Output shafts

- Stub axles

Special Milling Machines

For special milling applications, WINMAR offers machines with multi-axis movement and interpolation. By performing the primary material removal task, they save time needed for subsequent operations. WINMAR special milling machines can be offered for operations such as cam lobe milling, profile milling, keyway milling, groove milling, slot milling, and pad milling.

Typical Components

- Transmission shaft

- Gear shift drum

- Crank shaft

- CRI nozzle body