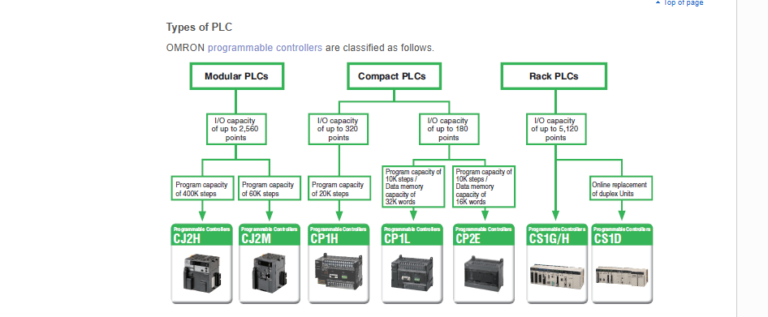

1. Types of OMRON PLCs:

- Compact PLCs: These are small, modular controllers designed for applications where space is limited. They are typically used for simpler control systems.

- Modular PLCs: These are more flexible systems, often used for large-scale applications with more complex control needs.

- Advanced PLCs: These PLCs are suitable for high-end applications, offering more features like advanced networking, I/O control, and real-time processing.

2. OMRON PLC Programming:

- Ladder Logic (LD): Most commonly used for PLC programming. It resembles electrical relay logic and is easy to understand for engineers familiar with relay-based control systems.

- Structured Text (ST): A high-level programming language for complex computations, similar to Pascal or C.

- Function Block Diagram (FBD): Used for complex systems that require graphical representations of control logic.

- Instruction List (IL): A low-level programming language, similar to assembly, though not as commonly used today.

- Sequential Function Chart (SFC): Used for sequential control processes.

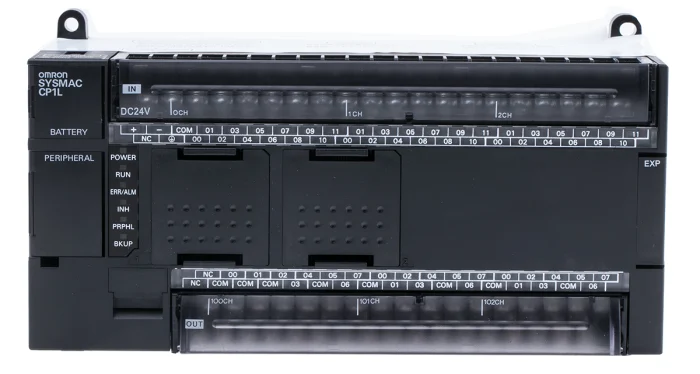

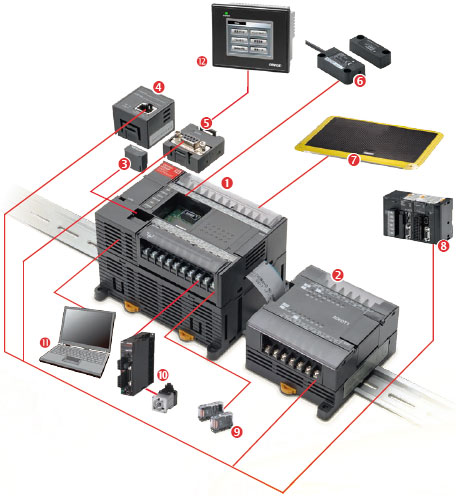

3. OMRON PLC Hardware Components:

- CPU Unit: The central processing unit of the PLC, responsible for executing the program.

- I/O Modules: These modules interface the PLC with external devices like sensors, actuators, and switches.

- Power Supply Unit: Provides the necessary power for the PLC to function.

- Communication Modules: Enable communication between the PLC and other devices, such as HMI (Human-Machine Interface) systems, SCADA systems, or other PLCs.

- Expansion Units: Additional units can be added to increase I/O capacity or provide more specialized functions.

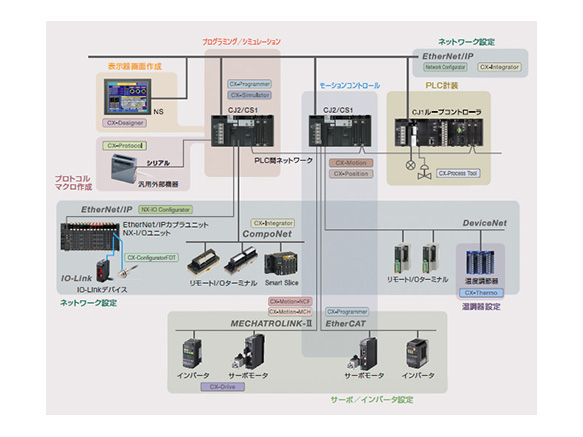

4. OMRON PLC Communication Protocols:

- Ethernet/IP: For high-speed industrial communication.

- Modbus/TCP: A widely-used protocol for data exchange between industrial devices.

- FINS (Factory Intelligent Network Service): OMRON’s proprietary protocol for communication between PLCs, HMIs, and other devices.

- Profibus, Profinet, DeviceNet: Common industrial protocols for fieldbus communication.

5. OMRON PLC Software Tools:

- CX-Programmer: OMRON’s primary software for programming PLCs. It supports Ladder Logic, Structured Text, and other languages.

- CX-Designer: Used for creating and programming HMI screens to interface with OMRON PLCs.

- Sysmac Studio: A powerful development environment for the NJ/NX series, combining PLC programming with motion control, robotics, and HMI design.

- CX-One: A software suite that includes CX-Programmer, CX-Designer, and other tools for complete PLC and device management.

6. OMRON PLC Features:

- High-Speed Processing: Advanced PLCs offer high-speed processing for complex operations like motion control, robotics, and vision systems.

- Networking and Connectivity: OMRON PLCs are designed for easy integration into industrial networks using Ethernet, fieldbus, and wireless protocols.

- Modular Expandability: Modular PLCs allow users to expand I/O capacity, add specialized modules, or integrate various automation devices.

- Remote Access: Many OMRON PLCs support remote access and control via web-based platforms or through software like CX-Server.

7. Applications of OMRON PLCs:

- Manufacturing Automation: PLCs are used to control machinery like conveyor belts, robotic arms, assembly lines, and packaging systems.

- Process Control: Used in chemical, oil, and gas industries to monitor and control processes such as mixing, heating, and fluid handling.

- Building Automation: Managing HVAC systems, lighting, and other critical systems in commercial buildings.

- Automotive Industry: Used in robotics, welding, painting, and testing stations for automotive assembly.

- Food & Beverage: Ensuring efficient control over production lines, temperature control, and packaging processes.

8. Advantages of OMRON PLCs:

- Reliability: OMRON PLCs are known for their durability and reliability in harsh industrial environments.

- Scalability: From small systems to large-scale operations, OMRON PLCs can be easily scaled up or down depending on the application.

- Ease of Use: With user-friendly programming software and intuitive hardware design, OMRON PLCs are accessible to both beginners and advanced users.

- Support & Documentation: OMRON provides comprehensive manuals, online support, and a large community of users for troubleshooting and advice.

9. Troubleshooting and Maintenance:

- Diagnostics: OMRON PLCs feature diagnostic tools for identifying system issues, including LED indicators and error codes.

- Maintenance: Regular maintenance of the PLC hardware and software is essential for long-term performance. This may include software updates, battery replacement, and cleaning of the physical components.

Conclusion:

OMRON PLCs are highly versatile and powerful automation devices that serve a wide range of industries, from manufacturing and process control to building automation. Whether you are working with a compact or advanced modular PLC, understanding the basics of programming, hardware components, and network integration is key to successfully implementing OMRON PLC systems in your automation projects.