InnoMaint FSMS helps your organization meet stringent food quality standards such as USDA, FDA, IFS, ISO 22000 group etc and ensure food safety throughout the food supply chain.

Trusted By Organizations

How Innomaint FSMS Benefits Food & Beverage Manufacturers

Clear Work Instructions

Let all stakeholders know the standard operating procedures with easily accessible and understandable multimedia digital checklists.

Boost Efficiency

Automates manual processes, such as scheduling maintenance checks and generating reports, saving you time and resources.

Trigger Work Orders at the

Right Time

Let work orders get triggered automatically upon preset conditions based on vibration, temperature, power, pressure, or humidity readings.

Instant Failure Alerts

Bring food processing, preservation, packing equipment etc., that fails back into operation quickly with immediate IoT based mobile alerts for quick notice.

Reduce Costs

By identifying potential issues early on and automating maintenance, you can avoid costly downtime and repair expenses.

Deliver Consistent Quality

Quickly identify potential issues by automating approval workflows, tracking quality control measures, and including testing and inspection results. So you can

Stay Up-to-Date on Regulations

Stay compliant with changing regulations and requirements, reducing the risk of fines or legal action.

Innomaint Food Safety Management Software

Features for Food & Beverage Industry

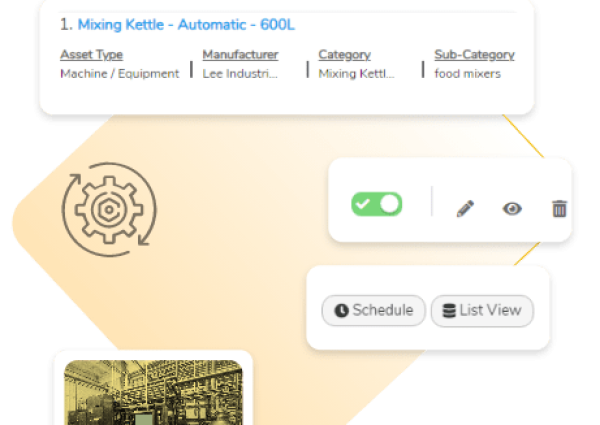

Asset Management

Asset management in food manufacturing industries helps to track, maintain, and optimize the equipment, machinery, and physical assets used in food production processes. By ensuring proper maintenance, calibration, and traceability of assets, Innomaint asset management enhances food safety, minimizes contamination risks, ensures regulatory compliance, reduces downtime through preventive maintenance, and improves overall operational efficiency.

- Helps maintain equipment in optimal condition

- Easier to identify the specific asset involved

- Minimizes the risk of equipment breakdowns

Work order Management

Work order management in food manufacturing industries helps to plan, execute, and document maintenance and operational tasks for equipment, facilities, and processes. By providing structured workflows, assigning tasks to appropriate personnel, ensuring timely responses to issues, and documenting maintenance activities.

- Enable quick response to issues

- Assign tasks to appropriate personnel

- Ensures that necessary corrective actions are taken

Facility Management

Food safety management software facility management enables the food & beverage industry at many locations with multiple facilities to oversee its complete Asset and facility management, Repair, and Maintenance program. It automates repetitive operations and effectively using resources enable facilities to operate at high productivity and efficiency levels.

- Helps management make specific decisions for your facility

- Enhance team collaboration and workflow efficiency

- Helps to utilize all spaces effectively

IoT Asset & Energy Monitoring

IoT sensors track equipment maintenance and usage data to help organizations monitor their food processing continuously and get better visibility of their energy consumption and wastage. They can keep track of the storage and transport conditions and ensure that they’re within safe windows.

- Ensure that the food is safe to consume

- Track and manage energy consumption

- Make data-centric decisions and improve energy efficiency

Condition Based Maintenance

Perform maintenance only when it is genuinely necessary as indicated by sensors fitted to heavy equipment so that utilization rates of equipment is maximum for production cycles.

- Reduce unnecessary and frequent routine maintenance expenses

- Predict failures before they occur intelligently

- Reduce manual intervention for monitoring tasks

Audit Management

Perform digital audits accurately, error-free and at lightning speeds rehearsing for external food safety audits and inspections from the comfort of your work cubicle.

- Exclusive workflow for Fixed Asset Auditing

- Easily trace the source of lag in quality

- Complete freedom from paper records

Equipment Tracking

Innomaint tracks equipment maintenance and usage data, helps to create and schedule preventive maintenance tasks. Preventive maintenance involves regularly scheduled inspections and maintenance tasks designed to detect and correct potential problems before they cause downtime or damage to equipment.

- Reduce downtime and extend the life of equipment

- Detect and correct potential problems before they cause downtime

- Reduce waste and prevent production delays

Mobile Application

Bring out the power of teamwork with clear, timely and effective communication via mobile app and quickly raise service requests via a simple QR code scan.

- Automatic reporting from the maintenance crew’s mobile device

- Real-time notifications on automatic work assignment and alerts

- QR Code scan to access the asset service details instantly

Documentation Management

InnoMaint provides a central repository for all safety-related documentation, such as checklists, SOPs, and training records. Proper documentation management can help organizations ensure regulatory compliance, reduce maintenance costs, and improve operational efficiency.

- Ensure consistency and accuracy in maintenance procedures

- Accurate and up-to-date maintenance records

- Help demonstrate compliance with regulatory requirements

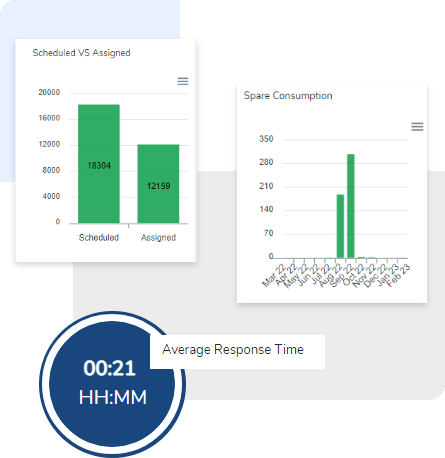

DashBoard & Real Time Data

The Dashboard provides real-time visibility into operations and maintenance status of assets. View all KPI metrics such as MTTR, MTBF, SLA compliances & much more.

- Real-time reporting and analytics for monitoring safety compliance

- Customizable dashboards for tracking safety metrics and KPIs

- Know the count of outstanding tasks at any moment

Integration with other systems

InnoMaint can integrate with other systems, such as inventory management and ERP systems, can help reduce manual data entry and streamline processes. This can save time and reduce the risk of errors.

- Streamline workflows, save time, and reduce errors

- More complete understanding of equipment performance